Products

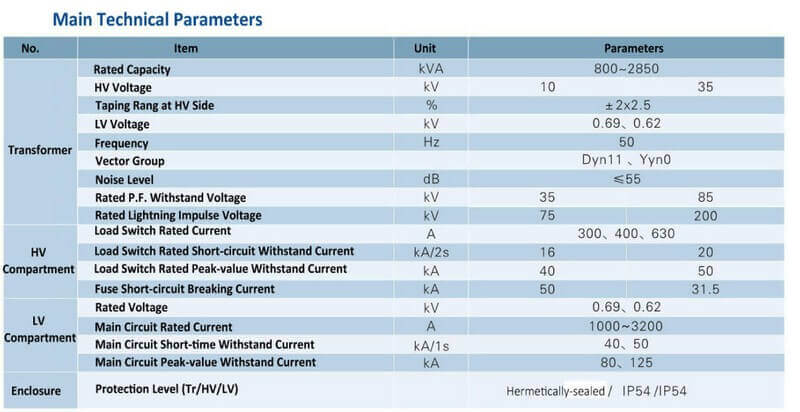

The pad-mounted transformer consists of the body of transformer, oil-immersed load switch, protection fuse, and the high and low voltage connection which are placed in a sealed oil-tank, equipping with a full range of operational monitoring instruments, such as pressure gauge, oil level gauge, oil temperature gauge, etc. and combining with the low voltage switchgear combination as a set of booster equipment.

1.Rated Capacity: 1600 kVA

2.HV rated voltage: 10-35 kV

3.Rated LV voltage: 0.38 kV (Customized )

4.Constructive form: Pad-mounted

5.Frequency: 50/60Hz

6.Vector Group: Dyn11

7.Phase: Three-phase

1.High safety protection

2. Complete functions and reliable performance

3. Flexible structure, sealed tank construction

4. Convenient maintenance

5. Low power consumption and energy saving

6. Low-noise, self-cooled overload capabilities

7. High protection level and weathering resistance

8. High mechanical strength and leakage-free

Application and After-Sales Service:

Application and After-Sales Service:Application: apartment buildings, schools, hospitals, shopping centers, or industrial sites.

After-sales Service: We have a professional aftersales engineer team, each aftersales engineer has more than 3 years of experience. And we also have localized technical backup to offer timely support in Malaysia, South Africa, Egypt, Dubai, UAE, Brazil.

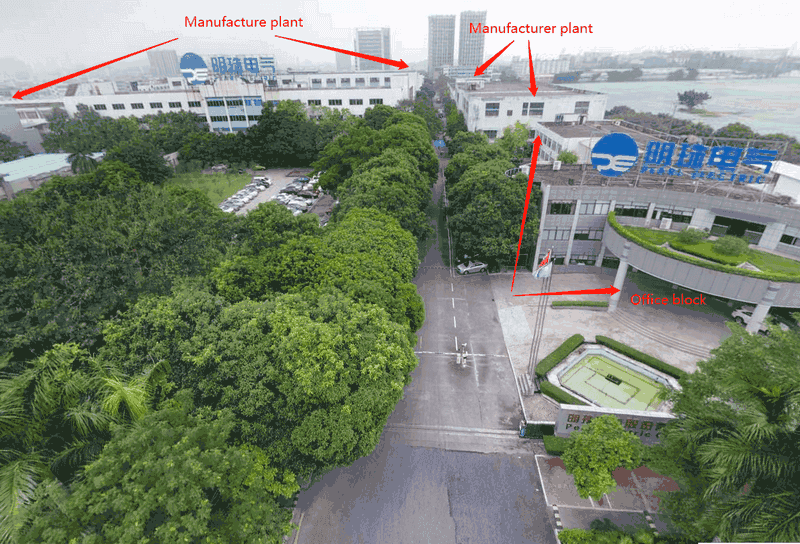

Workshop:

Established in 1958, located in Guangzhou City, Pearl Electric Co., Ltd is one of the most prominent power transformer manufacturers in China which design, produce and supply power transformers in domestic and abroad with almost 660 employees, more than 260 sets of specialized manufacturing equipment.

Pearl Electric is Top brand in China for Class 1E dry type transformer of nuclear power plant application and industrial-leader for new energy application substation transformer and energy conservation transformer, covering an area of 100,000 m2 among more than 70,000 m2 of modern factory workshop.

Accessories:

Pressure Relief Valve

Lifting Lugs

Filter Valve

Oil Temp Indicator

Winding Temp Indicator

Liquid Level Gauge

Off-Load Tap Switch

Wiring & Terminal Box

Rating & Terminal Marking Plate

Ground Pads

HV and LV Air Terminal & Gauging Chamber

Oil Filling Hole

Load Break Switch

Current Limiting Fuses

Surge Arresters

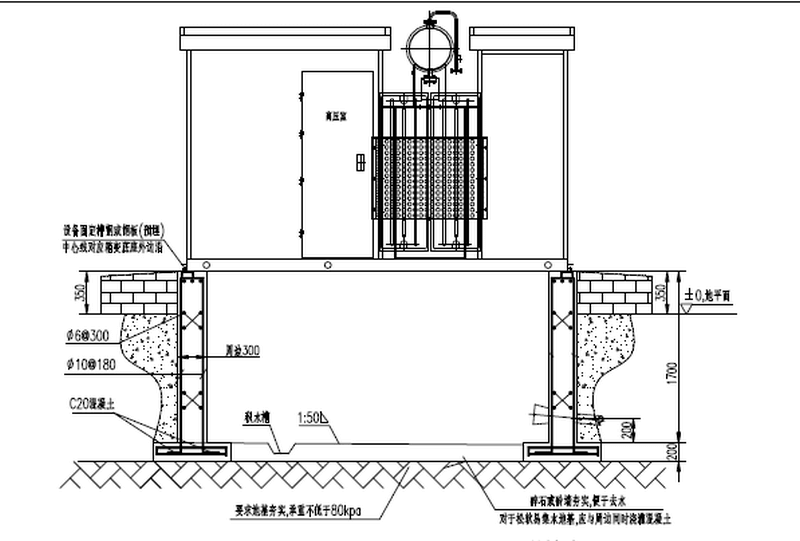

Installation Notices:

1. The base should be made far from the flat bog area, to avoid water drenching.

2. The base top should be located in a high place and 100~400mm above the ground.

3. Cable supporting rack should be made on the basis and firmly fixed, with certain mechanical strength to avoid any shaking or loosing.

4. The base should be of sufficient mechanical strength to prevent any sinking, which may cause equipment damage.

5. The surface of the base should be on the same level and smooth. If necessary, please use the level bar to check the base surface, thus ensuring no equipment distortion will happen due to poor base conditions. The uneven base surface may make the door opening difficult.

6. The earthing resistance and earthing cross-section should meet corresponding national standards, industry standards, and regulations specified by the local power administration authorities.

Copyright © Pearl Electric Co., Ltd.