Products

Cast Resin Dry Type Excitation Transformer is an excitation transformer applied to a static self-excitation system, since power is supplied to the generator’s excitation winding via the three-phase bridge rectifier, the current flowing through the excitation transformer windings is a non-sinusoidal current component containing high-order harmonics.

1.Rated power: 1000kVA

2.Primary voltage: 10kV

3.Secondary voltage: 0.4kV

4.Frequency: 50Hz/60Hz

5.Vector group: Dyn11

6.Insulation class: H/F Class

7.Application: Excitation system

1.Longer service time than oil transformers.

2.Compact appearance, lightweight than same level oil transformer which is more conveniently for delivery east installation.

3.Harsh environments and resistance to fire.

4.Large working capacity, have a higher capacity to distribute electricity to public places.

5.Friendly to the surrounding environment with safety and minimizing pollution

Technical

| Transformer type | Cast resin dry type transformer |

| Transformer Model | 1000kVA 10/0.4kV |

| Short circuit impedance | 6% |

| Noise Level | 50dB |

| Cooling mode | AN/AF |

| Winding material | Copper/Aluminum |

| Degree of protection | IP00 |

| HV tapping | +/-2*2.5% |

| Insulation material | Cast resin (HV) Pre-impregnated (LV) |

| Insulation level | Primary: 28kV AC Secondary: 3kV AC |

| BIL | 75kV for primary circuit |

| Type of installation | Indoor |

| Maximum attitude | <1000m |

| Standards | IEC60076-11 |

characteristics for 1000kVA 10kV cast resin dry type transformer

Application: Static excitation system of the hydropower plant and thermal power plant.

After-sales Service: We have a professional aftersales engineer team, each aftersales engineer has more than 3 years of experience. And we also have localized technical backup to offer timely support in Malaysia, South Africa, Egypt, Dubai, UAE, Brazil.

Paints shall only be thinned and/or mixed in accordance with the Manufacturer’s instructions and all paints, solvent, resins, hardness and associated products shall be stored and used strictly in accordance with the Manufacturer’s instructions and the applicable toxic, flammability, and safety requirements for the particular products.

Before painting or filling with oil, gas, or compound, all un-galvanized parts shall be thoroughly cleaned, free from rust, scale, burrs, grease, and moisture and all external rough surfaces on castings shall be filled.

| External Surfaces | |

| Apparatus | Painting |

| All ungalvanised surfaces other than nuts, bolts and washers which may be removed for maintenance | One priming coat of corrosion inhibiting paint applied immediately after cleaning.

Three coats of non-glossy, oil and weather-resisting paint applied after inspection, testing and before despatch |

| Exposed, ungalvanised nuts, bolts and washers which may be removed for maintenance | One coat of oil and weather resisting, non fading paint applied after erection |

| Panels, cubicles, kiosks and apparatus boxes, for use indoors | Three coats of paint |

Succeeding coats of paints shall be applied only after the previous coat is thoroughly dry to ensure a satisfactory finish. The final dry film thickness of outer painted surfaces shall not be less than 90 microns.

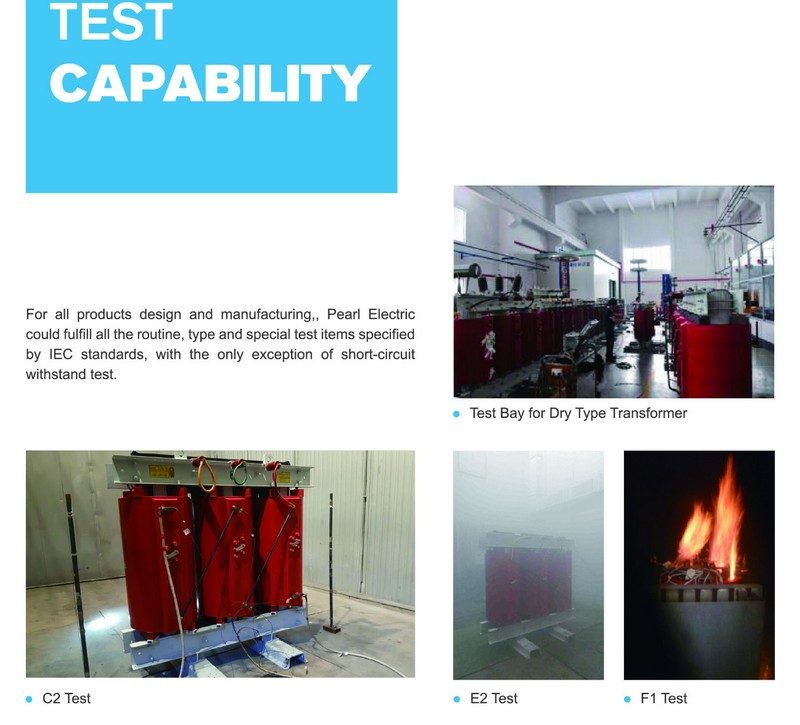

Test Capacity:

Test capability is an important part to show Pearl Electric’s high quality and R&D results. And each transformer must pass all tests before delivery.

1. Except short-circuit transformer, we can do all routine tests, type tests,s and special tests for our transformer.

2. Having 4 test bays covered Dry-type transformer, oil-immersed power transformer, and transformer substation.

3. Getting a complete set of third-party test certificates for the transformer, included KEMA, CESI, ASTA, CTQC, CNAS.

Our Partner:

Our Service:

1.OEM is available.

2.Your inquiry related to our product & price will be replied to within 24 hours.

3.Well-trained & experienced staff are to answer all your inquiries in English

4.Working time: 8:00 am ~17:00 pm, Monday to Friday. (UTC+8)

5.Customized solution & perfect after-sale service

6.Payment: We can accept T/T, L/C.

7.For large orders, engineers can be sent to your country for on-site maintenance instructions.

Copyright © Pearl Electric Co., Ltd.